Equipment downtime resulting from component failure is not merely an operational annoyance; it represents a direct, quantifying hit to your bottom line. When a standard spring snaps under high tension, production lines halt, safety risks skyrocket, and maintenance costs accumulate with alarming speed. Here is the deal: you simply cannot rely on generic, hardware-store components for high-stress industrial applications. A heavy duty extension spring serves as the engineered solution designed specifically to withstand extreme pulling forces, resist fatigue, and ensure the operational longevity of your heaviest machinery.

1. What defines a heavy duty extension spring?

A heavy duty extension spring is a mechanical device specifically engineered to absorb and store significant potential energy while resisting extreme pulling forces. You might be wondering what truly separates these robust components from the standard springs found in lighter, everyday applications. The distinction lies primarily in the wire diameter, the specific material composition, and the tension-to-weight ratio capability. Unlike standard custom extension springs that might deform permanently under just a few hundred pounds of load, these components are manufactured to handle thousands of pounds of force without ever reaching their elastic limit.

These springs are characterized by extremely tight coils that press firmly against each other when in a resting position, creating a significant amount of what is known as initial tension. But here is the key: heavy duty classifications are not arbitrary marketing terms; they are strictly defined by the spring index—the ratio of mean coil diameter to wire diameter—and the tensile strength of the alloy used. While a standard spring might use basic music wire, a heavy duty variant utilizes high-carbon steel or chrome silicon alloys treated specifically to prevent permanent elongation under heavy stress.

High-tension capabilities explained

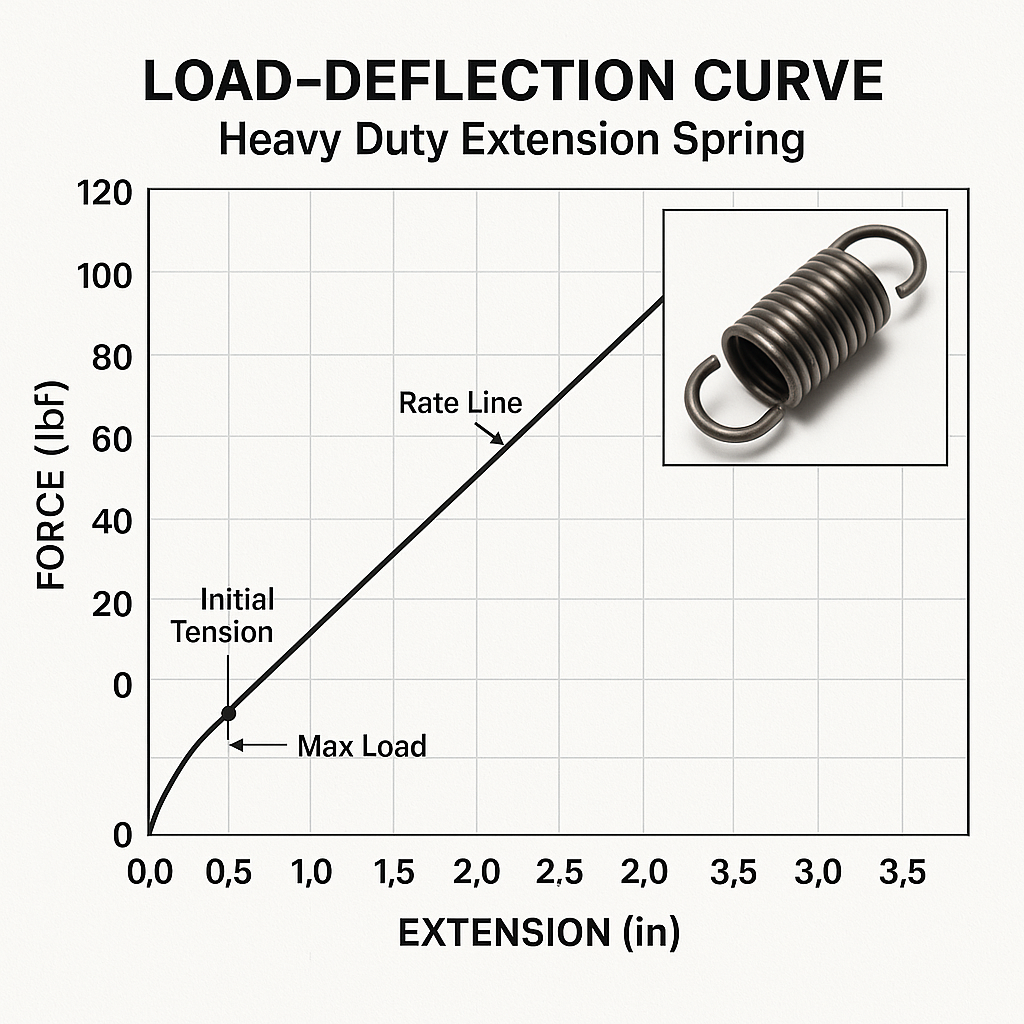

In the realm of heavy machinery, “tension” is not just a force; it is a critical specification. Initial tension is the force required to separate the coils before any actual extension occurs. In heavy duty designs, this initial tension is maximized to ensure the assembly remains rigid and secure until the intended operational load is applied. The elastic limit represents the maximum stress the material can endure without suffering permanent deformation, while the working load is the optimal range where the spring operates indefinitely without fatigue.

Wire diameter differences

When you visually examine a heavy duty spring, the most obvious indicator of its capability is the wire gauge. Standard springs often feature wire diameters measured in mere thousandths of an inch, whereas heavy duty versions frequently utilize wire diameters ranging from 0.148” up to 0.625” or even larger. Why does this matter? The cubic relationship between wire diameter and strength means that even a minuscule increase in thickness yields a massive, exponential increase in load capacity and overall durability.

Is it just about size?

Size is certainly a factor, but metallurgy is the true differentiator in performance. You could theoretically have a thick wire made of low-grade steel that fails significantly faster than a thinner wire made of high-grade Chrome Silicon. The bottom line is that heavy duty status is a sophisticated combination of geometry and material science. You must evaluate the tensile strength of the wire grade, not just the physical dimensions, to ensure the component meets your specific industrial requirements.

2. How does a heavy duty extension spring function?

A heavy duty extension spring functions by absorbing energy through resistance to a pulling force, extending its length and storing potential energy in the process. When you attach one end to a fixed point and pull the other, the coils separate, and the material attempts to pull back to its original close-wound position with equal force. This is where it gets interesting: this action is governed by Hooke’s Law, which states that the force needed to extend the spring is directly proportional to the distance it is stretched, provided the material stays within its elastic limit.

The mechanics rely heavily on the initial tension we discussed earlier, which acts as a preload. Think about it: before the spring even begins to extend, you must overcome that initial internal force holding the coils together. Once that threshold is passed, the spring extends linearly. In heavy duty applications, this linear response is critical for predictable machine behavior, ensuring that a 500lb load always results in the exact same extension distance every single time.

Storing potential energy

Energy transfer is the core purpose of the spring, converting kinetic energy from the load into potential elastic energy. This stored energy then provides the return force necessary to bring the mechanism back to its starting position. In many industrial setups, the spring also acts to dampen shock loads, smoothing out the operation of heavy doors or gates. You need to know that the energy storage capacity is finite. If you extend the spring beyond its design parameters, the steel yields, and the spring loses its ability to return to zero.

Hook and loop mechanics

The hooks or loops serve as the critical interface between the spring body and your machinery. But here is the kicker: these are mechanically the weakest points of the entire spring assembly. While the body distributes stress relatively evenly across many coils, the hook concentrates all that pulling force and torque onto a single bend radius. In heavy duty functioning, the specific design of the hook—whether crossover, machine, or swivel—dictates the lifespan of the entire assembly more than the coil body itself.

How is tension generated?

Tension is generated during the specialized coiling process known as back-winding. Manufacturers intentionally twist the wire against its natural curvature as it is fed into the coiling machine. What does this mean for you? It means the spring is “pre-loaded” with force. For heavy duty applications, this back-winding is aggressive, ensuring the spring remains rigid and unresponsive to minor vibrations or light loads, activating only when the intended heavy load is applied.

| Parameter | Description | Importance in Heavy Duty |

|---|---|---|

| Spring Rate (k) | Force required to extend 1 unit of length | Determines stiffness; high rate = heavy duty |

| Initial Tension (Pi) | Force keeping coils together at rest | Prevents “looseness” in heavy machinery |

| Maximum Deflection | Max travel before material yield | Crucial for preventing permanent damage |

| Elastic Limit | Point of permanent deformation | Defines safety margin for heavy loads |

3. Where is a heavy duty extension spring typically used?

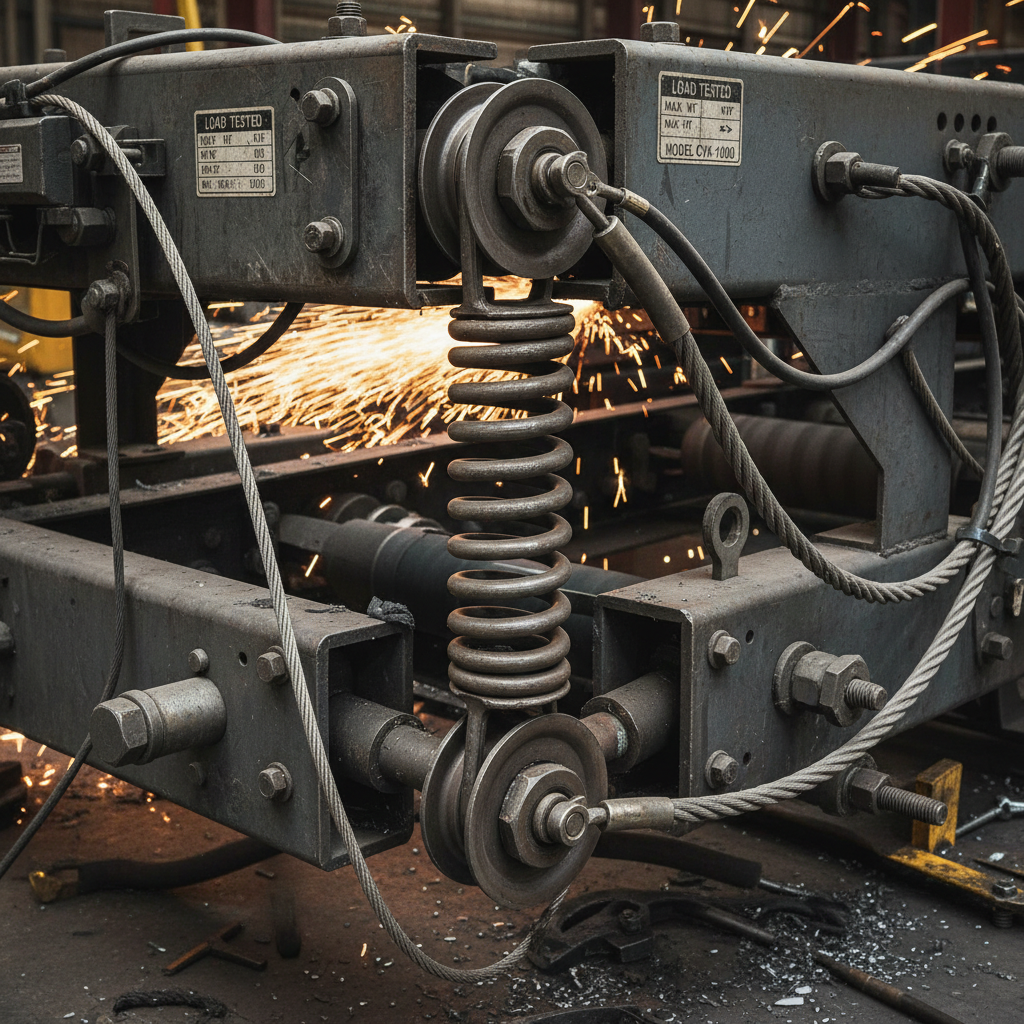

You will find heavy duty extension springs operating in the most punishing environments on the planet, from the subterranean depths of oil wells to the high-impact world of construction sites. Here is the reality: any mechanism that requires a return force for a load exceeding 100 lbs likely utilizes these custom spring solutions. They are the silent, reliable muscles behind heavy garage doors, massive farm equipment, and complex assembly line robots.

Specifically, in the oil and gas sector, these springs are critical for downhole tools and rig safety mechanisms where failure is absolutely not an option. Consider this: a failure on an oil rig costs thousands of dollars per minute in lost production. Therefore, these industries demand springs that can withstand not just the mechanical load, but also harsh environmental factors like saltwater, chemical exposure, and extreme temperature fluctuations.

Industrial machinery roles

In the industrial sector, heavy duty extension springs are ubiquitous. Conveyor systems use them to tension heavy belts to prevent slippage under load. Stamping presses rely on them to return the massive press head to the neutral position after each cycle. Dock levelers utilize them to counterbalance the immense weight of the loading ramp, allowing a single operator to move a steel plate weighing hundreds of pounds.

Agricultural equipment needs

Farming machinery faces a unique set of challenges including mud, debris, and constant, violent vibration. But here is the deal: a tractor plow hitting a rock relies on a heavy duty extension spring to allow the plow blade to “trip” or fold back, preventing the plow from breaking. Once the obstacle is cleared, the spring snaps the blade back into position. This “trip spring” application requires high fatigue resistance to handle thousands of cycles over a planting season.

Can they handle aerospace loads?

While aerospace engineering often prefers compression springs for weight savings, extension springs are used in landing gear latching mechanisms and cargo bay doors. What is the catch? Aerospace applications demand exotic materials like Titanium or Inconel to handle the load while resisting extreme temperature changes. A standard steel spring would become brittle and snap at high altitudes, so material selection becomes the primary engineering challenge.

4. What materials suit a heavy duty extension spring?

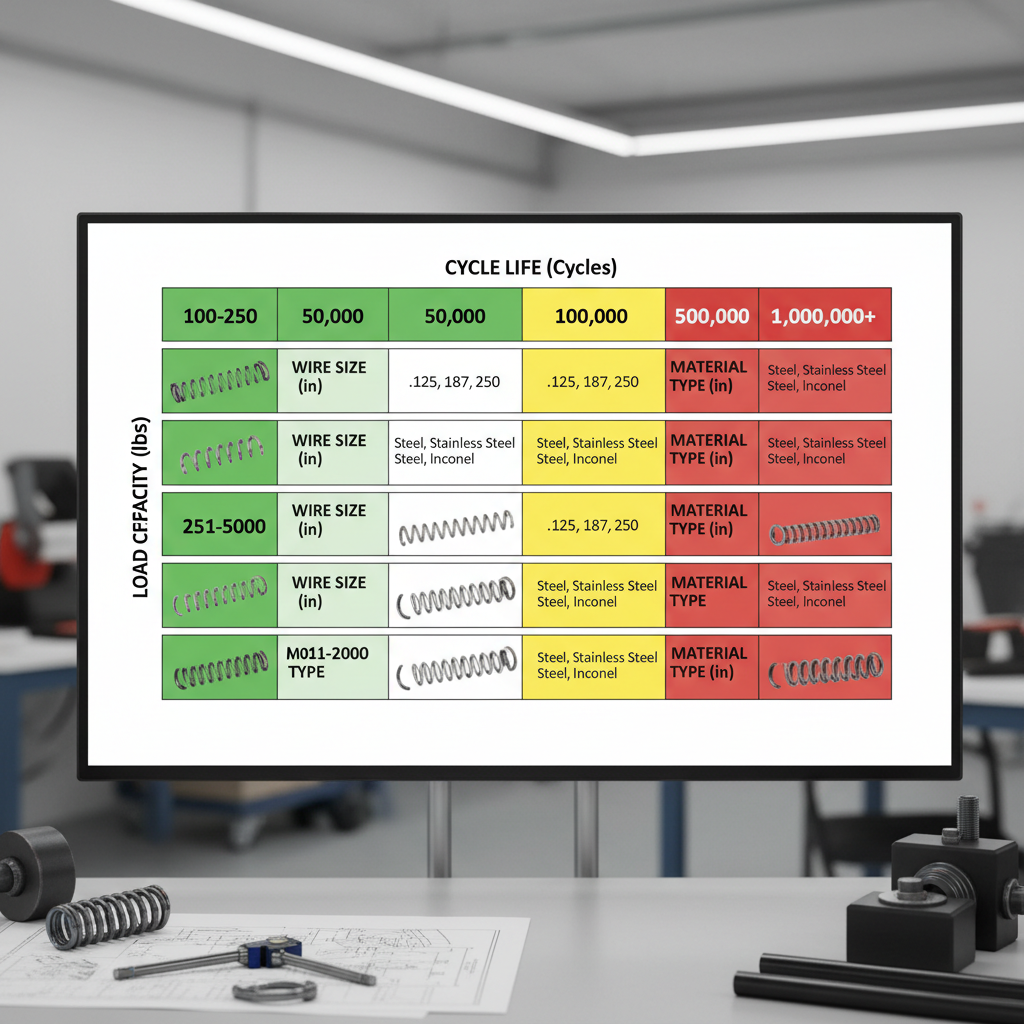

Selecting the right material is the single most critical decision in designing a heavy duty spring that will last. Let’s be honest: standard stainless steel often lacks the tensile strength required for true heavy duty applications. While it offers corrosion resistance, it cannot match the load-bearing capacity of high-carbon steel alloys. For extreme loads, engineers inevitably turn to Oil-Tempered MB (ASTM A229) and Chrome Silicon (ASTM A401).

These materials are drawn and heat-treated to maximize their yield strength and durability. Here is the secret: Chrome Silicon is the gold standard for high-stress, impact-loaded springs. It withstands higher temperatures and higher stresses than standard carbon steel. If your application involves shock loading—like a gun recoil spring or a heavy industrial hammer—Chrome Silicon is likely the mandatory choice.

Chrome silicon advantages

Chrome Silicon offers distinct advantages for heavy duty applications. It operates effectively up to 475°F, making it suitable for engine compartments. It boasts superior resistance to cyclic fatigue, meaning it can cycle more times before breaking. Most importantly, it handles shock loads without fracturing. Imagine if you used a material that lost its tension after just one hour of operation. That is what happens when you use music wire in a high-heat environment.

Why use oil-tempered wire?

Oil-tempered wire is the workhorse of the heavy duty spring world. Here is the deal: it is cost-effective and incredibly strong. The wire is heated, quenched in oil, and tempered to produce a uniform microstructure. It is ideal for torsion bars, large suspension springs, and garage door springs. However, it will rust instantly if left unprotected, so it almost always requires painting, powder coating, or plating for longevity.

Stainless steel durability

You typically avoid stainless for “heavy duty” in terms of raw load, but for “heavy duty” in terms of environment, it is king. But wait: 17-7 PH Stainless Steel bridges the gap. It is a precipitation-hardening alloy that offers strength comparable to music wire but with the corrosion resistance of stainless. For marine heavy duty applications, 17-7 PH is the superior, albeit more expensive, option.

| Material | ASTM Grade | Max Temp (°F) | Key Characteristic |

|---|---|---|---|

| Oil Tempered | A229 | 300°F | General purpose heavy loading |

| Chrome Silicon | A401 | 475°F | Shock loads & high stress |

| Stainless 17-7 | A313 | 650°F | High strength + Corrosion resistance |

| Music Wire | A228 | 250°F | High strength, small diameters only |

5. How do you design a heavy duty extension spring?

Designing a heavy duty spring is a delicate balancing act between the physical space available and the force required. Here is the truth: you cannot simply “make the wire thicker” to get more strength if you don’t have the space for the increased coil diameter. Engineers must utilize professional spring engineering services to calculate the precise Spring Rate (k), which is the force required to deflect the spring one unit of distance.

The formula for spring rate is $k = (G * d^4) / (8 * D^3 * N)$, where $G$ is the shear modulus, $d$ is wire diameter, $D$ is mean diameter, and $N$ is the number of active coils. Pay attention to this: the wire diameter ($d$) is to the fourth power. This means a tiny increase in wire thickness results in a massive, exponential increase in stiffness. This mathematical reality is the most powerful tool in a designer’s arsenal for creating heavy duty performance in compact spaces.

Calculating initial tension

Initial tension is the force holding the coils together, and it is a critical design factor. You need to realize that initial tension is not infinite. There is a limit to how much tension can be wound into a spring based on the spring index. If you design a spring requiring impossible initial tension, the manufacturer will not be able to produce it. A general rule is that initial tension can account for roughly 10-25% of the total load capacity.

Determining maximum load

Maximum load is defined as the point just before the spring permanently deforms or takes a “set.” But here is the catch: you never design a spring to operate at its maximum load. You design it to operate at roughly 75-80% of max load to provide a necessary safety factor. Operating at 100% capacity drastically shortens the fatigue life, leading to early, catastrophic failure.

What is the spring rate?

Spring rate is the constant that defines the spring’s “personality” or stiffness. A high rate means a stiff, unyielding spring; a low rate means a soft, compliant spring. Here is the deal: In heavy duty applications, consistency is key. You need a spring rate that is linear and predictable, ensuring that when your 2-ton door moves 6 inches, the counterbalancing force increases by the exact calculated amount, preventing accidents.

6. Why does a heavy duty extension spring fail?

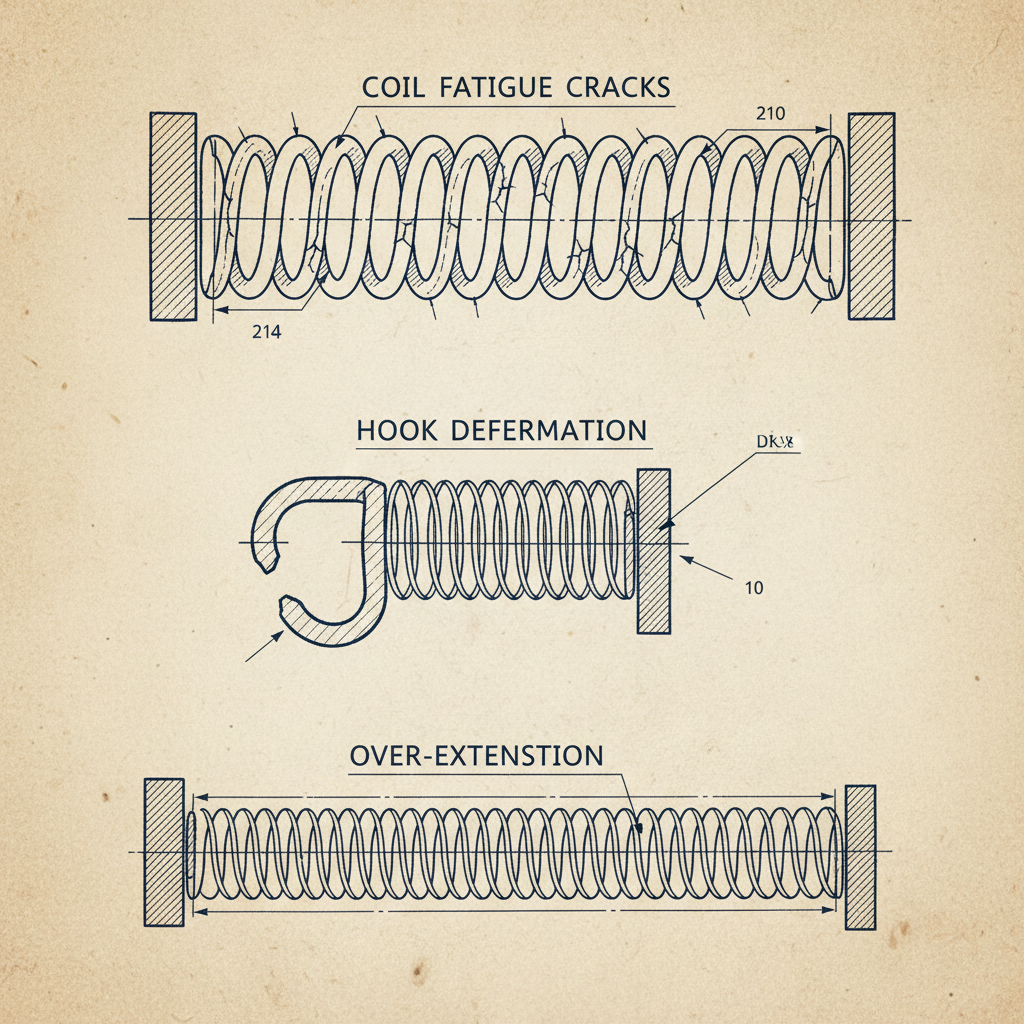

Understanding failure modes is the first and most important step to prevention. Here is the reality: the most common failure point for any extension spring is the hook. While the body of the spring distributes stress relatively evenly, the hook concentrates all the pulling force and torque onto a single curved section of wire. This stress concentration makes the hook the undeniable “Achilles’ heel” of the heavy duty spring.

Fatigue is the silent killer in industrial applications. Consider this: every time the spring extends and retracts, invisible micro-cracks form on the surface of the wire. Over thousands of cycles, these cracks propagate until the wire snaps. In heavy duty applications where loads are high, this process is accelerated. Shot peening is a manufacturing process often used to bombard the surface with pellets, compressing the outer layer and significantly extending fatigue life.

Understanding fatigue limits

Fatigue limit refers to the maximum stress level a material can withstand for an infinite number of cycles. However, most springs operate within a finite cycle life. You must ensure that your spring operates within its stress limits. If you push a spring to full extension repeatedly, you are operating in the high-stress zone where cycle life drops from 100,000 to perhaps only 5,000. For high-cycle applications, you must design a physically larger spring that operates at a lower percentage of its maximum stress.

Overstressing the hooks

The transition radius where the coil body turns into the hook is where stress peaks dramatically. But here is the solution: using swivel hooks or “extended hooks” can sometimes alleviate torsional stress, but the best solution is often to use a different end configuration entirely. A threaded plug screwed into the coils transfers force to the entire coil body rather than a single bent wire, virtually eliminating hook breakage.

Is corrosion the main enemy?

In outdoor or chemical environments, corrosion pits the surface of the wire. Think about it: a rust pit is essentially a pre-made crack. Once corrosion sets in, the fatigue limit of the material plummets. Hydrogen embrittlement is another risk, particularly if the spring was plated (like zinc plating) without being properly baked afterwards to release trapped hydrogen gas, leading to spontaneous snapping.

7. How do you measure a heavy duty extension spring?

Accurate measurement is critical, especially when ordering a replacement for a broken part to get your machine back online. Here is the deal: guessing is not an option. You typically need a digital caliper to get precise readings, particularly for the wire diameter, as a difference of 0.010″ can double the spring’s strength. When contacting a manufacturer, you need four key dimensions.

First is the Length Inside Hooks (LIH). Pay attention: do not measure the total overall length including the thickness of the wire at the ends. Measure the space inside the loops where the mounting hardware will sit. This is the functional length of the spring. Next is the Body Length, which is the length of the coiled section only.

Measuring length inside hooks

Length Inside Hooks (L.I.H.) is the distance between the inner surfaces of the hooks or loops. This dimension determines if the spring will fit onto your mounting points. The Body Length is the length of the coil stack, excluding the hooks. The Overall Length is the tip-to-tip length, but this is less useful for engineering purposes. You might be wondering why measuring the body length matters if you have the LIH. The body length tells the manufacturer how many coils are active.

Wire diameter verification

Measure the wire diameter in the center of the spring body, not near the loops where the wire might have been stretched or distorted during manufacturing. Here is a pro tip: measure the wire in two directions (90 degrees apart) to ensure it is round and not oval-shaped due to wear. This ensures you are getting an accurate reading of the material thickness.

Do you need calipers?

For heavy duty springs, yes. A tape measure is not accurate enough for wire diameter or outer diameter (OD). But here is the catch: for the Length Inside Hooks on a very large spring (e.g., 2 feet long), a tape measure is acceptable. For the OD and Wire Diameter, calipers are mandatory to ensure the replacement spring fits in the designated channel or tube without binding.

| Dimension | Abbreviation | Tool Needed | Criticality |

|---|---|---|---|

| Wire Diameter | d | Micrometer/Caliper | High (Impacts Rate) |

| Outer Diameter | OD | Caliper | High (Fitment) |

| Length Inside Hooks | LIH | Tape/Caliper | High (Install point) |

| Body Length | BL | Caliper | Medium (Active coils) |

8. Why choose a custom heavy duty extension spring?

Stock springs are great for prototyping, but they rarely fit the exacting demands of heavy industrial machinery. Here is the reality: a stock catalog offers “close enough,” but in high-stakes environments, “close enough” leads to premature failure and safety hazards. Choosing a custom wire form or spring allows you to tailor the spring rate to your specific load curve, ensuring the machine operates exactly as intended.

Furthermore, stock springs typically come with standard machine loops. But what if your mounting point requires an extended hook, a carabiner-style clip, or a threaded insert? Custom manufacturing allows for complex end configurations that integrate seamlessly with your assembly, eliminating the need for dangerous workarounds or adapters that can introduce new failure points.

Specific load requirements

Every machine has a unique force curve that changes throughout its range of motion. Here is the deal: a custom design allows you to specify exactly how much force the spring should exert at extension point A and extension point B. This precision prevents motor burnout from springs that are too stiff, or gate sagging from springs that are too soft.

Environment-specific coatings

Stock springs usually come plain or zinc-plated, which is minimal protection. Imagine if your equipment operates on an oil rig in the North Sea. You need Cadmium plating, epoxy powder coating, or specialized Teflon finishes to survive the salt spray. Custom manufacturing gives you access to these advanced surface treatments that extend the life of the part by years, not months.

When is stock sufficient?

Stock is sufficient for repairs on non-critical equipment or for initial prototyping to test fitment concepts. However, once you move to production or critical safety applications, the liability associated with a generic part outweighs the small cost savings. Custom springs provide traceability and material certification that stock parts often lack, which is crucial for compliance.

9. How to maintain a heavy duty extension spring?

Maintenance is often overlooked until a loud bang signals a catastrophic failure. Here is the truth: extension springs are dynamic components that degrade over time. However, a simple maintenance schedule can double or triple their service life. The primary enemy is friction—specifically, friction between the coils and friction at the hook contact points.

Lubrication is essential for longevity. You might be wondering what type of oil to use. A heavy, penetrating spray grease (like lithium grease) is ideal because it seeps between the coils and the mounting hardware. This prevents metal-on-metal grinding at the hook interface, which is where most wear occurs. It also creates a barrier against moisture, preventing rust that leads to fatigue cracking.

Routine inspection cycles

You should perform visual checks quarterly. Look for gaps between coils when the spring is relaxed; this is a sign of yield or stretch. Check for thinning metal at the loop connection, which indicates abrasive wear. Look for rust pitting, especially deep pits, which act as stress risers. But here is the key: you must measure the spring periodically. If the “Length Inside Hooks” has increased while the spring is unloaded, the steel has stretched. A stretched spring is a ticking time bomb—replace it immediately.

Lubrication best practices

Do not use WD-40 or light solvents; they evaporate quickly and offer little long-term protection. Here is the deal: use a non-drying silicone or lithium-based lubricant. Apply it while the spring is slightly extended to ensure it coats the inner surfaces of the coils. This reduces the internal friction as the coils separate and close, smoothing out the operation.

Signs of wear to watch for

Squeaking is the first auditory sign of trouble. Pay attention: if your spring squeaks, it is crying out for lubrication. If it clanks or rattles, it may have lost tension. If you see shiny, worn patches on the hooks, the mounting hardware is eating into the spring steel, and failure is imminent. Catching these signs early prevents downtime.

10. What ensures heavy duty extension spring safety?

When a heavy duty extension spring breaks under load, it becomes a dangerous, high-velocity projectile. Here is the reality: the energy stored in the stretched coils is released instantly, turning the steel fragments into shrapnel. To protect personnel and machinery, safety containment is not optional; it is mandatory. The most common and effective method is using a safety cable.

A safety cable is a steel wire rope that runs through the center of the spring and is secured at both ends. Imagine if the spring snaps; instead of flying across the factory floor, the broken coils are captured by the cable. This simple addition costs pennies but saves lives. For larger springs, a “drawbar” design or an enclosed tube (spring guard) can be used to fully contain the mechanism.

Correct installation methods

Never force a spring installation. Here is the deal: if you have to over-stretch the spring just to get it onto the hooks, you are damaging it before it is even used. Use a spring puller tool or adjust the tensioning mechanism to allow for a zero-tension install, then tighten the system to the required preload. Contact us for guidance on proper installation procedures for large springs.

Using safety cables

There are several containment methods. A through-rod is a solid rod inside the spring. A cable is a flexible steel cable threaded through the center. An enclosure is a pipe or box surrounding the spring. You need to know that the safety cable must be strong enough to hold the weight of the mechanism if the spring fails. It serves as the ultimate backup support.

Why is preload important?

Preload ensures the spring is always under slight tension, preventing it from unhooking during operation. But here is the catch: too much preload eats into your working travel. It is vital to calculate the exact preload required to keep the hooks seated without overstressing the coils. This balance keeps the system safe and operational.

| Safety Feature | Function | Application |

|---|---|---|

| Safety Cable | Catch broken spring | Garage doors, Overhead equipment |

| Spring Guard | Contain shrapnel | High-speed machinery |

| Drawbar | Compresses on failure | Critical load bearing |

| Proper Preload | Prevent unhooking | Vibrating machinery |

Conclusion

Heavy duty extension springs are the silent powerhouses of the industrial world, bridging the gap between static load bearing and dynamic motion. Here is the bottom line: whether you are powering agricultural machinery or stabilizing oil rigs, the reliability of your operation hinges on the quality of these components. Ignoring the nuances of material selection, initial tension, and safety containment is a recipe for costly downtime.

Don’t settle for “good enough” when your machinery demands the best. At Zigoal, we combine decades of metallurgical expertise with advanced CNC manufacturing to deliver springs that perform under pressure. Contact our spring experts today to solve your toughest tension challenges. Let’s build a solution that doesn’t just work, but lasts.

FAQ Section

Q1: What distinguishes a heavy duty extension spring from a standard spring?

A heavy duty extension spring is defined by its ability to handle high loads and resist fatigue, typically achieved through larger wire diameters (often >0.125″), higher initial tension, and the use of superior alloys like Oil-Tempered or Chrome Silicon steel compared to standard music wire.

Q2: How do I measure the length of my heavy duty extension spring?

To accurately measure for replacement, measure the “Length Inside Hooks” (L.I.H.), which is the distance between the inner surfaces of the loops. Do not measure the overall length tip-to-tip, as this varies based on wire thickness and does not reflect the functional install length.

Q3: Can heavy duty extension springs be repaired if the hook breaks?

Generally, no. While you can technically bend up a new loop from the remaining coils, this alters the spring rate, reduces the coil count (making it stiffer), and uses wire that is already fatigued. It is strongly recommended to replace the spring entirely to ensure safety and proper load handling.

Q4: What is the strongest material for a heavy duty extension spring?

Chrome Silicon (ASTM A401) is widely considered the best material for high-stress and impact applications due to its high tensile strength and heat resistance. For corrosive environments, 17-7 PH Stainless Steel offers the best balance of high strength and corrosion resistance.

Q5: Why is initial tension important in heavy duty extension springs?

Initial tension is the force required to start separating the coils. It is crucial in heavy duty applications to ensure the spring remains rigid and holds a load firmly in the closed position, preventing “slop” or unwanted movement in the mechanism until the intended force is applied.